Researchers have developed an inkjet printing technique that can be used to print optical components such as waveguides. Because the printing approach can also fabricate electronics and microfluidics, it could advance a variety of devices such as optical sensors used for health monitoring and lab-on-a-chip devices that integrate and automate multiple laboratory functions onto a small circuit, or chip.

“Inkjet printing is a very attractive method for fabricating optical components because the positions and sizes of features can easily be modified and there is virtually no material waste,” said Fabian Lütolf, a member of the research team led by Rolando Ferrini at CSEM in Switzerland. “However, the surface tension of the inks makes it difficult to print lines with a specific height, which is necessary to create a waveguide.”

Inkjet printing is an additive manufacturing technique that uses tiny nozzles like the ones found in desktop inkjet printers to deposit a computer-generated pattern of drops (the “ink”) onto a substrate to build a structure. The researchers discovered that depositing the ink in two steps, rather than the traditional single step, enabled printing of lines with a specific height and with much smoother features than would otherwise be possible. The printed structures are considered to have 2.5 dimensions because although they are not flat, their complexity is limited compared to structures created with traditional 3D printing.

In The Optical Society (OSA) journal Optics Express, the researchers show that their technique can be used to print 2.5D optical waveguides and tapers made of acrylic polymer. The printing concept can also be used with other materials such as metallic inks to make electronics or sucrose mixtures for biodegradable applications.

Lütolf points out that although printing of electronics is already used commercially, printing microfluidics is more challenging and prone to the same problems as waveguides. “The fact that our approach could allow components with multiple functionalities to be fabricated with a single printer paves the way toward additive manufacturing of entire integrated circuits on chips,” said Lütolf. “This means that optical components could be added to flexible hybrid electronics and that optoelectronic components such as light sources or detectors could be integrated into printed optical circuits.”

Read more: Researchers create precision optical components with inkjet printing

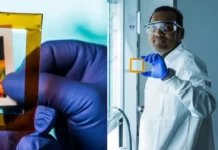

thumbnail courtesy of phys.org