Mechanical engineering researchers are inventing game-changing technologies and developing a Renaissance in 3-D printing.

In the mid-15th century, a new technology that would change the course of history was invented. Johannes Gutenberg’s printing press, with its movable type, promoted the dissemination of information and ideas that are widely recognized as a major contributing factor for the Renaissance.

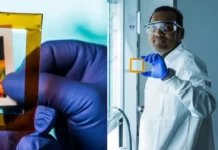

Over 500 years later, a new type of printing was invented in the labs of MIT. Emanuel Sachs, professor of mechanical engineering, invented a process known as binder jet printing. In binder jet printing, an inkjet printhead selectively drops a liquid binder material into a powder bed — creating a three-dimensional object layer by layer.

Sachs coined a new name for this process: 3-D printing. “My father was a publisher and my mother was an editor,” explains Sachs. “Growing up, my father would take me to the printing presses where his books were made, which influenced my decision to name the process 3-D printing.”

Sachs’ binder jet printing process was one of several technologies developed in the 1980s and ’90s in the field now known as additive manufacturing, a term that has come to describe a wide variety of layer-based production technologies. Over the past three decades, there has been an explosion in additive manufacturing research. These technologies have the potential to transform the way countless products are designed and manufactured.

One of the most immediate applications of 3-D printing has been the rapid prototyping of products. “It takes a long time to prototype using traditional manufacturing methods,” explains Sachs. 3-D printing has transformed this process, enabling rapid iteration and testing during the product development process.

This flexibility has been a game-changer for designers. “You can now create dozens of designs in CAD, input them into a 3-D printer, and in a matter of hours you have all your prototypes,” adds Maria Yang, professor of mechanical engineering and director of MIT’s Ideation Laboratory. “It gives you a level of design exploration that simply wasn’t possible before.”

Throughout MIT’s Department of Mechanical Engineering, many faculty members have been finding new ways to incorporate 3-D printing across a vast array of research areas. Whether it’s printing metal parts for airplanes, printing objects on a nanoscale, or advancing drug discovery by printing complex biomaterial scaffolds, these researchers are testing the limits of 3-D printing technologies in ways that could have a lasting impact across industries.

Improving speed, cost, and accuracy

There are several technological hurdles that have prevented additive manufacturing from having an impact on the level of Gutenberg’s printing press. A. John Hart, associate professor of mechanical engineering and director of MIT’s Laboratory for Manufacturing and Productivity, focuses much of his research on addressing those issues.

Read more: A new era in 3-D printing

Image courtesy of mit.edu

Related Links:

Cost and Time Savings of Using 3D Printing to Fabricate Automotive Components