Fused silica glass

The material, dubbed Glassomer, consists of amorphous quartz-glass particles with a diameter of about 100 nm, mixed in with the monomer hydroxyethyl methacrylate (HEMA) and the solvent phenoxyethanol (POE). Bastian Rapp and his colleagues at the Karlsruhe Institute of Technology in Germany then polymerized the material, which became a solid at room temperature. The glass nanoparticles constitute about 60 percent of the mixture by volume.

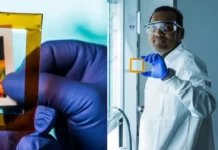

The researchers carved a chunk of Glassomer into a small flower shape with a small knife and also subjected the material to high-throughput subtractive machining processes that are routinely used to shape polymer parts: milling, lathing, and ablation with a femtosecond infrared laser.

Scatterings image

With Glassomer, glass components like these can be produced by cutting. [Image: Markus Breig, KIT]

To create the finished glass pieces, the scientists subjected the Glassomer shapes to a process called thermal debinding: heating the pieces to 800 ºC to burn off the polymer matrix, which becomes carbon dioxide, leaving the silica behind as a solid. At this stage, the material looks slightly brown. Finally, the shapes were sintered at 1,300 ºC, which closes the tiny pores between the original particles, leaving only the shaped glass.

Read more: Glass That’s Handled Like a Polymer

thumbnail courtesy of osa-opn.org