In a laboratory at the University of Rochester, researchers are using lasers to change the surface of metals in incredible ways, such as making them super water-repellent without the use of special coatings, paints, or solvents.

The commercial applications of the technology range from de-icing of commercial airplanes and large trucks, to rust and corrosion prevention of exposed metal surfaces, to cleaner, anti-microbial surfaces for surgical and medical facilities.

But to make the technology commercially viable, the lasers must become much more powerful.

A venture capital-backed technology company, FemtoRoc Corp., is undertaking a joint research project with John Marciante, an associate professor of optics, and the University’s Institute of Optics to develop those more powerful lasers. The project, expected to take six years, has a research budget estimated at $10 million.

“What they [FemtoRoc] need is a high-powered, ultra-fast, femtosecond-class laser system with average power measured in kilowatts, rather than the 10’s of watts now commercially available,” says Marciante. “So, we need to scale up by over a factor of 10.”

It’s a very ambitious undertaking.

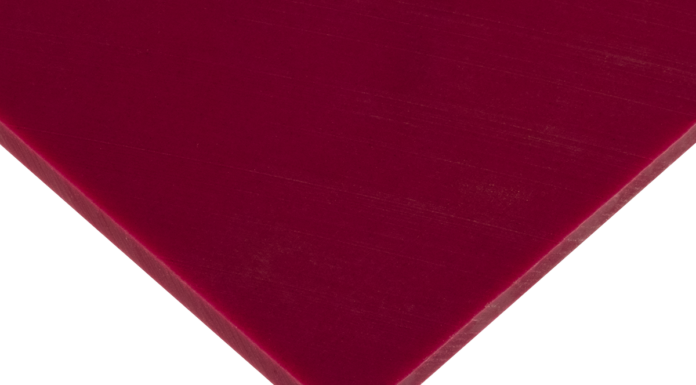

The proprietary, super-hydrophobic technology uses lasers to create an intricate pattern of micro and nanoscale structures, giving the treated metal surfaces a new set of physical properties.

Read more: A laser focus on super water-repellent metals

thumbnail courtesy of phys.org