Turning 320 mammoth bones from scan into scientifically accurate reconstruction

Leuven, Belgium – 2018. Materialise NV (Nasdaq: MTLS) is realizing its largest Stereolithography project yet – a life-size, 3D-printed reconstruction of the first mammoth skeleton that was ever displayed in Western Europe. The 320 bones making up the skeleton were scanned and digitally reconstructed and will still be printed, finished and fitted with a customized frame to hold up the skeleton. From October onwards, the 3D-printed mammoth will be on display in the Belgian city of Lier, the place where the original mammoth was found.

Since 1869, the Mammoth of Lier has been on display at the Royal Belgian Institute of Natural Sciences in Brussels. Almost 150 years later, it is returning to its roots in Lier – albeit in a significantly more modern form. The entire skeleton will be 3D printed by Materialise, in close collaboration with the museum in Brussels, and mounted on a quasi-invisible internal structure.

Reconstructing the mammoth presented a significant challenge for the Materialise engineers. Every one of the mammoth’s 320 bones was scanned at the museum in Brussels, and then the skeleton was digitally reconstructed in close collaboration with their resident paleontologist to achieve the highest degree of anatomical accuracy. Each scan also needed to be cleaned up and prepared for the 3D printer with Materialise Magics software, since a scan simply produces a 3D image instead of a structurally sound 3D form that is suitable for 3D Printing.

Instead of using the original 19th century exterior mounting system, a more sophisticated interior mount structure made of carbon will be created and integrated inside the plastic bones – meaning that in the digital phase, Materialise engineers already had to think about how to fit the structure within the bones, integrating entry and exit holes in the bones for the carbon tubes. For the modular carbon structure, Materialise drew on the experience of its daughter company RapidFit in the automotive tooling. The result is a sturdy and lightweight structure weighing a mere 300 kg in total.

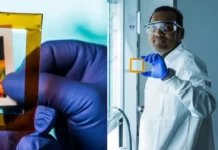

The bones will be printed on nine of the aptly named Mammoth Stereolithography printers at Materialise, which were specially designed by the company to realize projects that require extra-large printer capacity (with a printer bed dimension of 220x70x80). Uniquely positioned to realize a project of this scale, Materialise will be using its full backbone of 3D printing services, starting from optimizing the scans for the printers, engineering the mounting structure inside the bones and printing the mammoth on the most suitable 3D printing technology from the company’s extensive printing facility. Applying 1/10th of a millimeter of resin at a time, the mammoth will take more than one month to print, before being finished and painted with a combination of different paints, textures, and lacquers so the bones can match the original skeleton as precisely as possible.

Gertjan Brienen, Project Manager at Materialise, says “The scale of the project is challenging, particularly because we had to bring different experts together, including engineers, paleontologists, and finishing specialists, and align our vision of the finished model, all while meeting tight deadlines. The original skeleton presents some inaccuracies which reflect the knowledge at the time of the original mounting 150 years ago. One example is the length of its tail, which we now know is shorter than initially thought. The original mammoth skeleton is also missing a few bones, including its left tusk. We mirrored the right tusk and recreated it in Materialise 3-matic to achieve a more precise replica than the wooden tusk that was used to complete the original skeleton. The broken upper jaw was also restored accurately by mirroring the original bone structure. This means the 3D-printed mammoth will be more scientifically accurate than the original.”

Materialise is no stranger to archeological projects and has previously worked on 3D printed reconstructions of the bodies of King Tutankhamun and Ötzi the Ice Mummy. For this project, they worked closely with the resident paleontologist of the Royal Belgian Institute of Natural Sciences, Dr. Mietje Germonpré.

“3D Printing is increasingly proving to be an extremely useful tool in the field of paleontology, allowing us to study fossils without damaging the precious originals, and collaborate virtually on the same fossil with colleagues around the world. Working on the first entire mammoth skeleton ever to be 3D printed has been a unique experience.”

– Dr. Mietje Germonpré.

About Materialise

Materialise incorporates more than 25 years of 3D printing experience into a range of software solutions and 3D printing services, which together form the backbone of the 3D printing industry. Materialise’s open and flexible solutions enable players in a wide variety of industries, including healthcare, automotive, aerospace, art and design, and consumer goods, to build innovative 3D printing applications that aim to make the world a better and healthier place. Headquartered in Belgium, with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the largest 3D printing facilities in the world. For additional information, please visit: www.materialise.com

Press contacts:

Kristof Sehmke

Corporate Communications Manager, Materialise

Phone: +32 477 70 22 60

Email: press@materialise.com

Twitter: @MaterialiseNV

Visit: www.materialise.com