A cross-institutional research team has designed a unique porous structure they call “metallic wood” because of its high strength-to-weight ratio.

Researchers are constantly seeking materials that are high-strength but low weight, similar to the properties of titanium. Key to achieving these is the way in which a metal’s atoms are stacked, and also maintaining that arrangement in the manufacturing process, which has been tricky.

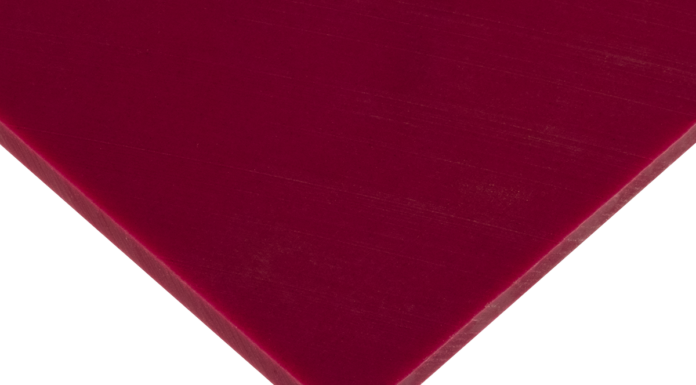

Researchers at the University of Pennsylvania, the University of Illinois at Urbana–Champaign, and the University of Cambridge believe they’ve achieved a breakthrough in this aim with the development of a new material they’ve dubbed “metallic wood”: a sheet of nickel with nanoscale pores that make it as strong as titanium but four to five times lighter.

Key to material’s behavior are the pores’ empty spaces as well as the self-assembly process in which they’re made, which make the metal similar to a natural material, such as wood, explained James Pikul, assistant professor in the Department of Mechanical Engineering and Applied Mechanics at Penn Engineering in a news release.

“The reason we call it metallic wood is not just its density, which is about that of wood, but its cellular nature,” he said. “Cellular materials are porous; if you look at wood grain, that’s what you’re seeing—parts that are thick and dense and made to hold the structure, and parts that are porous and made to support biological functions, like transport to and from cells.”

Similarly, the empty space between the pores also can be used to support another function with the infusion of other materials, Pikul said. For example, putting inside the scaffolding an anode and cathode material could allow it to form a double function as a battery as well as whatever industrial designed part it is, he said.

No Accident

The metal’s similarity to wood is no accident. The team took inspiration from the natural world to try to overcome the limitation of the atomic arrangement of metals, the best natural examples of which even have defects that limit their strength.

If materials researchers could achieve a block of titanium where every atom was perfectly aligned with its neighbors, the result would be 10 times stronger than what can currently be produced. They typically can’t, however, so to solve this problem, some materials researchers have taken an architectural approach, designing structures with the geometric control necessary to unlock the mechanical properties that arise at the nanoscale, where defects have reduced impact.

Read more: ‘Metallic Wood’ Has Strength of Titanium, Density of Water

Image courtesy of University of Pennsylvania

Related Links:

This is ‘nanowood,’ an invention that could reduce humanity’s carbon footprint