Fillamentum, a Czech manufacturer of filaments for the 3D printing industry, is showcasing its new NonOilen filament at Expo 2020 in Dubai.

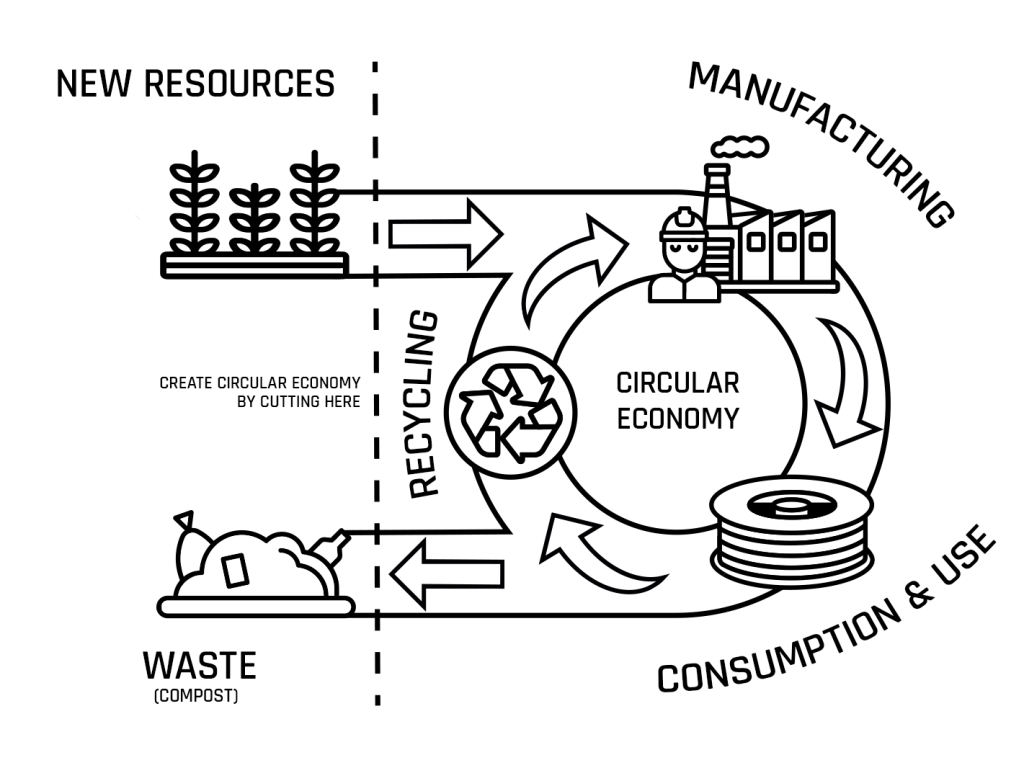

Developed in collaboration with the Slovak University of Technology, the polylactic acid/polyhydroxy butyrate blend (PLA/PHB) is 100% biodegradable and can be recycled several times without losing its functional properties. According to Fillamentum, NonOilen is also the company’s first filament to be made entirely out of 100% bio-renewable sources, in line with the firm’s goals of advancing the circular economy.

Josef Doleček, founder & CEO of Fillamentum, said, “In general, the idea of sustainability and recyclability is becoming the number one topic in companies across all industry sectors. Sustainability is one of the main principles of Fillamentum, which is ready to spread this respectful approach to the environment among other companies in order to ensure a quality life for future generations.”

Navigating a plastic world

It’s not a stretch to say almost every product we use these days relies on polymers in some way. The production of conventional polymers often requires oil, and most of it ends up in landfill at the end of its useful life (where it can stay for another few centuries). In the 3D printing sector, the most widely used polymer is PLA, which is known for its low cost and ease of use.

Although PLA is technically biodegradable, it still requires temperatures of around 60°C, a certain humidity, and a microbe-rich environment for degradation to occur. As these conditions aren’t that common in nature, breaking down PLA tends to call for the use of an industrial composting plant. And even then, PLA degradation takes longer than standard biodegradable waste and leaves behind microplastics which can harm local ecosystems.

Fillamentum’s NonOilen filament

Unlike conventional PLA, Fillamentum’s NonOilen filament is intended to be completely biodegradable in domestic composting units within just 90 days. As well as leaving behind no microplastics, the material can also be recycled and reused in several subsequent print jobs with minimal loss of properties. It decomposes about three times as fast as PLA thanks to the PHB component of the filament, which improves biodegradability and mechanical properties.

NonOilen is primarily characterized by its high strength, toughness, and hardness. It also offers a temperature resistance of up to 110°C and is reportedly as easy to print as PLA. With its natural silk look, the material is safe for food contact applications and can even be washed in a dishwasher.

Fremach, a supplier of polymer automotive components, has already used the material to 3D print parts such as control gauges and gears, owing to NonOilen’s resistance to high temperatures. Bicycle firm KCK Cyklosport has also leveraged the filament to 3D print components for a new bicycle helmet prototype.

Miroslava Pribylova, a Process Engineer at Fremach, adds, “With green prototyping, classic materials such as PLA, PETG or CPE are replaced by fully biodegradable and recyclable NonOilen. The benefits of 3D printing are obvious and are increasingly important to our business. Furthermore, Fillamentum’s ecological thinking motivates us to take our own steps closer to nature.”

Find NonOilen at Expo 2020 Dubai

Fillamentum’s Dubai exhibition is set to be partially interactive, whereby a robotic arm developed in collaboration with the Brno University of Technology and its spin-off, 3Deposition, will 3D print NonOilen parts for the duration of Expo 2020. The company has even developed a special version of NonOilen embedded with sand from Dubai specifically for the event.

Doleček said, “We are proud that we can introduce NonOilen at the Dubai World Exposition. It represents a whole new generation of materials developed with sustainability and environmental friendliness in mind from the very beginning.”

Learn more at the original article here.

Related Links:

3D Systems Breakthrough Material to Enable Digital Production of Plastic Parts