Ultrathin Photonic Material Cools Down Wearable Electronics: Overheating of wearable skin-like electronic devices increases the risk of skin burning and results in performance degradation. A research team led by City University of Hong Kong (CityU) invented a photonic material-based “soft, ultrathin, radiative-cooling interface” that greatly enhances heat dissipation in devices, with temperature drops more than 56°C, offering an alternative for effective thermal management in advanced wearable electronics.

Ultrathin Photonic Material Cools Down Wearable Electronics: Overheating of wearable skin-like electronic devices increases the risk of skin burning and results in performance degradation. A research team led by City University of Hong Kong (CityU) invented a photonic material-based “soft, ultrathin, radiative-cooling interface” that greatly enhances heat dissipation in devices, with temperature drops more than 56°C, offering an alternative for effective thermal management in advanced wearable electronics.

“Skin-like electronics are an emerging development in wearable devices,” said Dr Yu Xinge, Associate Professor in the Department of Biomedical Engineering (BME) at CityU, who co-led the research. “Effective thermal dissipation is crucial for maintaining sensing stability and a good user experience. Our ultrathin, soft, radiative-cooling interface, made of dedicatedly designed photonic material, provides a revolutionary solution to enable comfortable, long-term healthcare monitoring, and virtual and augmented reality (VR/AR) applications.”

In electronic devices, heat can be generated from both internal electronic components, when an electric current passes through a conductor, a process known as Joule heating, and external sources, such as sunlight and hot air. To cool down the devices, both radiative (i.e. thermal radiation – emitting heat energy from the device surface) and non-radiative (i.e. convection and conduction – losing heat to the layer of still air around the device and through direct contact with a cold object) heat-transfer processes can play a role.

However, the current technologies rely mostly on non-radiative means to dissipate the accumulated Joule heat. Moreover, the materials are usually bulky and rigid and offer limited portability, hindering the flexibility of wireless wearable devices.

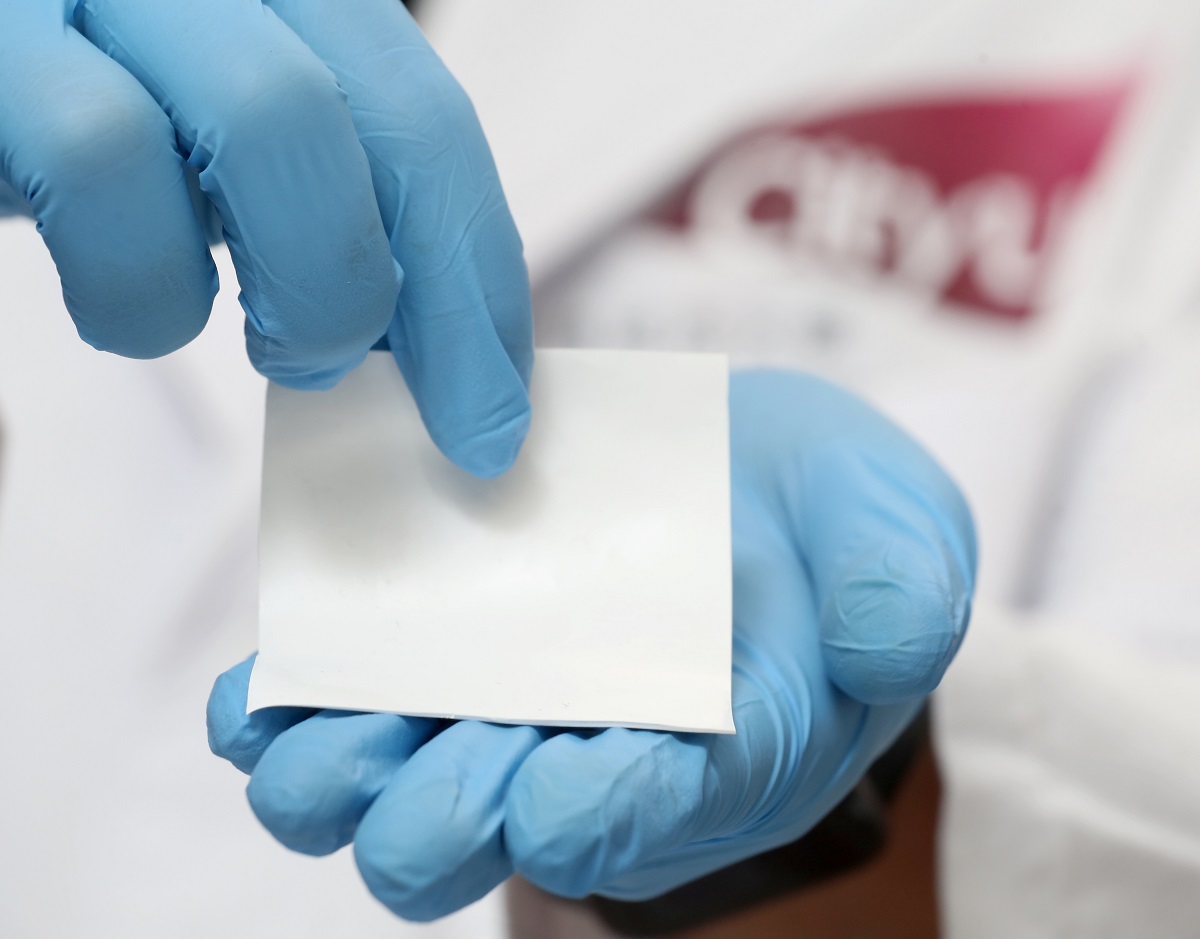

To overcome these shortcomings, the research team developed a multifunctional composite polymer coating with both radiative and non-radiative cooling capacity without using electricity and with advances in wearability and stretchability.

The cooling interface coating is composed of hollow silicon dioxide (SiO2) microspheres, for improving infrared radiation, and titanium dioxide (TiO2) nanoparticles and fluorescent pigments, for enhancing solar reflection. It is less than a millimetre thick, lightweight (about 1.27g/cm2), and has robust mechanical flexibility.

Ultrathin Photonic Material Cools Down Wearable Electronics: When heat is generated in an electronic device, it flows to the cooling interface layer and dissipates to the ambient environment through both thermal radiation and air convection. The open space above the interface layer provides a cooler heat sink and an additional thermal exchange channel. The interface also exhibits excellent anti-ambient-interference capability due to its lower thermal conductivity, making it less susceptible to environmental heat sources that would affect the cooling effect and performance of the devices.

To examine its cooling capacity, the cooling interface layer was conformally coated onto a metallic resistance wire – a typical component causing a temperature rise in electronics. With a coating thickness of 75 μm, the temperature of the wire dropped from 140.5°C to 101.3°C, compared with uncoated wire at an input current of 0.5 A, and dropped to 84.2°C with 600 μm thickness, achieving a temperature drop of more than 56°C.

“It is necessary to keep the device temperature below 44°C to avoid skin burns,” said Dr Yu. “Our cooling interface can cool down the resistance wire from 64.1°C to 42.1°C with a 150 μm-thick coating.”

With the efficient passive radiative cooling capacity and the sophisticated nonradiative thermal design, the performance of several skin electronic devices developed by the team significantly improved, including the efficiency of wireless power transfer to light emitting diodes (LEDs) and the signal stability of a skin-interfaced wireless sensor under environmental obstructions (e.g. sunlight, hot wind and water).

“The intrinsically flexible nature of the cooling interface allows the electronic devices to undergo stable cooling even under extreme deformation, such as bending, twisting, folding and stretching many times,” said Dr Lei Dangyuan, Associate Professor in the Department of Materials Science and Engineering (MSE) at CityU, another co-leader of the study.

Ultrathin Photonic Material Cools Down Wearable Electronics: For example, their cooling-interface-integrated stretchable wireless-based epidermal lighting system showed higher illumination intensity and maintained stable performance even upon stretching from 5% to 50% 1,000 times.

The team submitted a US patent application for the invention. They won a Gold Medal, one of 36 awards won by CityU teams, the highest number of awards among local institutions at the 48th International Exhibition of Inventions Geneva, with their project named “Cooling Technology for Epidermal Electronics”.

Next, the research team will focus on practical applications of the cooling interfaces for advanced thermal management of wearable electronics in the healthcare monitoring, wireless communications and VR/AR fields.

The findings were published in the scientific journal Science Advances under the title “Ultrathin, soft, radiative cooling interfaces for advanced thermal management in skin electronics”.

The first co-authors are Dr Li Jiyu, a postdoc in the BME, and Mr Fu Yang, a PhD student in the MSE at CityU. The corresponding authors are Dr Yu and Dr Lei.

The research is supported by CityU, the Hong Kong Centre for Cerebro-cardiovascular Health Engineering (COCHE) at InnoHK, and the Research Grants Council of Hong Kong.

Ultrathin Photonic Material Cools Down Wearable Electronics: Original Article

Japanese researchers develop ultrathin, highly elastic skin display