Wear, corrosion, material fatigue—these signs of degradation are common to most materials. This makes it all the more important to detect damage early, preferably on the micro-scale. Magnetic test methods are often used for this purpose, which was previously impossible with non-magnetic steel. Researchers from Kaiserslautern and Mainz have now developed a process in which they apply a thin magnetic layer to steel. Changes in the microstructure can thus be detected by changes in magnetic effects. Materials such as aluminum can also be tested in this way. The study was published in the Journal of Magnetism and Magnetic Materials.

Steel is one of the most frequently used materials. It is used in many variants including stainless steel, high-strength quenched and tempered steel, and low-priced structural steel. Steels can be magnetic or non-magnetic. They are used in cutlery, in-vehicle components or in steel girders for buildings and bridges. Sometimes, steel is exposed to high temperature or stress. “This can result in microstructural changes, cracks or component failure,” says Dr. Marek Smaga, who is a researcher at the Department of Materials Science under Professor Dr. Tilmann Beck at the Technische Universität Kaiserslautern (TUK). Experts speak in this context of material fatigue. Such damage is initially only visible at the micro-level. Even with magnetic testing methods, it is not yet possible to detect changes in this scale in non-magnetic steel at an early stage.

Engineers from the TUK and physicists from the Johannes Gutenberg-University Mainz (JGU) are presenting a solution in their current study. Their technique makes use of magnetic effects, even though it is being applied to a non-magnetic material. “With magnetic steel, it is possible to find changes in the structure early on,” explains the doctoral student from Kaiserslautern Shayan Deldar. “Even tiny deformations change the magnetic properties. This can be measured with special sensor technology.”

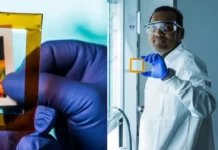

The researchers have coated a non-magnetic steel with magnetic films, each 20 nanometers thin, consisting of terfenol-D, an alloy comprising the chemical elements terbium, iron and dysprosium, or permalloy, a nickel-iron compound. The researchers then used a so-called Kerr microscope to check whether strains in the steel could be detected in the microscopic range. “This is achieved using the so-called Kerr effect,” explains Smaga, “which allows the magnetic microstructures, the so-called domains, to be imaged by rotating the polarization direction of light.”

Read more: Detecting damages in non-magnetic steel through magnetism

thumbnail courtesy of phys.org