Unlike composites made with a thermoset matrix, thermoplastic composites (TPCs) require neither complex chemical reactions nor lengthy curing processes. Thermoplastic prepregs require no refrigeration, offering practically infinite shelf life. The polymers used in aerospace TPCs — polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), polyetherketoneketone (PEKK) and polyarylketone (PAEK) — offer high damage tolerance in finished parts, as well as moisture and chemical resistance and, thus, do not degrade in hot/wet conditions. And they can be remelted, promising benefits in repair and end-of-life recyclability. But perhaps the greatest driver for TPC use in developing aircraft is the ability to join components via fusion bonding/welding. It presents an attractive alternative to the conventional methods — mechanical fastening and adhesive bonding — used to join thermoset composite (TSC) parts.

As defined in the widely cited paper, “Fusion Bonding/Welding of Thermoplastic Composites,” by Ali Yousefpour, National Research Council Canada (Ottawa, ON, Canada), “The process of fusion-bonding involves heating and melting the polymer on the bond surfaces of the components and then pressing these surfaces together for polymer solidification and consolidation.” The result is very different from thermoset joining.

“You are creating a unitized structure, such as a rib welded to a skin,” explains Arnt Offringa, head of Aerostructures R&T for GKN Fokker (Hoogeveen, The Netherlands). “When viewed under a microscope, you see just homogeneous polymer, so this is different than bonding. There is no dividing line, no split, no identifiable joining material such as adhesive. There is only one material, which is why you use the same polymer on both sides of the weld. Thus, authorities will accept such a join without mechanical fasteners.” (Offringa uses the word “join” here because the result of the welding process is not a joint, but one solid piece.)

In fact, such welded TPC structures have been flying for decades. And although resistance welding and induction welding are the two most established methods, others, including ultrasonic welding, laser welding, and conduction welding, are being advanced for use with composites. Development of these methods continues as welding proponents seek the necessary reliability in predictive process simulation software, increased inline control of welding process variables, and extension of welding processes to the production of aircraft primary structures.

Resistance welding

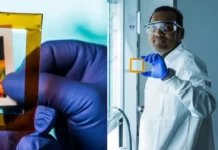

Along with KVE Composites Group (The Hague, The Netherlands), GKN Fokker is an acknowledged leader in TPC welding development (see CW’s tour of Fokker Aerostructures). “We started with resistance welding in the early 1990s,” says Offringa. “The elegance of this method is that heat is produced exactly at the weld interface.” An electric current passed through a resistive element at the weld interface, creates heat and melts the thermoplastic polymer (Fig. 1). However, this resistive element — a metal or carbon fiber (CF) — stays in the finished part. “We developed a method using a PPS-coated metal mesh as the resistive element, and then certified and flew resistance-welded CF/PPS main landing gear doors on the Fokker 50 turboprop aircraft in 1998,” says Offringa. “This then led to conversations with Airbus UK (Broughton, Chester, UK) and the development of glass fiber/PPS fixed leading edges for the A340/A350 and then A380 widebody aircraft.” GKN Fokker has continued its resistance welding research, focused mainly on carbon fiber-reinforced plastic (CFRP).

Read more: Welding thermoplastic composites

Image courtesy of compositesworld.com

Relate Links:

Quadrant EPP extends its product range by thermoplastic composites

Overmolding as enabler for composites, aerospace to automotive