Researchers find new material with significant potential for electronics applications

Diodes allow directed flows of current. Without them, modern electronics would be inconceivable. Until now, they had to be made out of two materials with different characteristics. A research team at the Technical University of Munich (TUM) has now discovered a material that makes it possible to create a diode with a simple change in temperature.

New Material Will Make Locally Flexible Diodes Possible: Manufacturing a diode generally involves combining two semiconducting materials with different properties. In most cases these are modified forms of silicon to which different elements are added to create the desired characteristics. This process is known as doping.

Doping with phosphorus, arsenic or antimony, which adds free electrons to the material, is called n-type doping. The n refers to the negatively charged electrons. Boron, aluminum and gallium, by contrast, bind electrons from the silicon, resulting in positively charged holes. The material is p-doped. Combining the two materials produces a diode that permits the current to flow only in one direction.

Temperature changes material characteristics

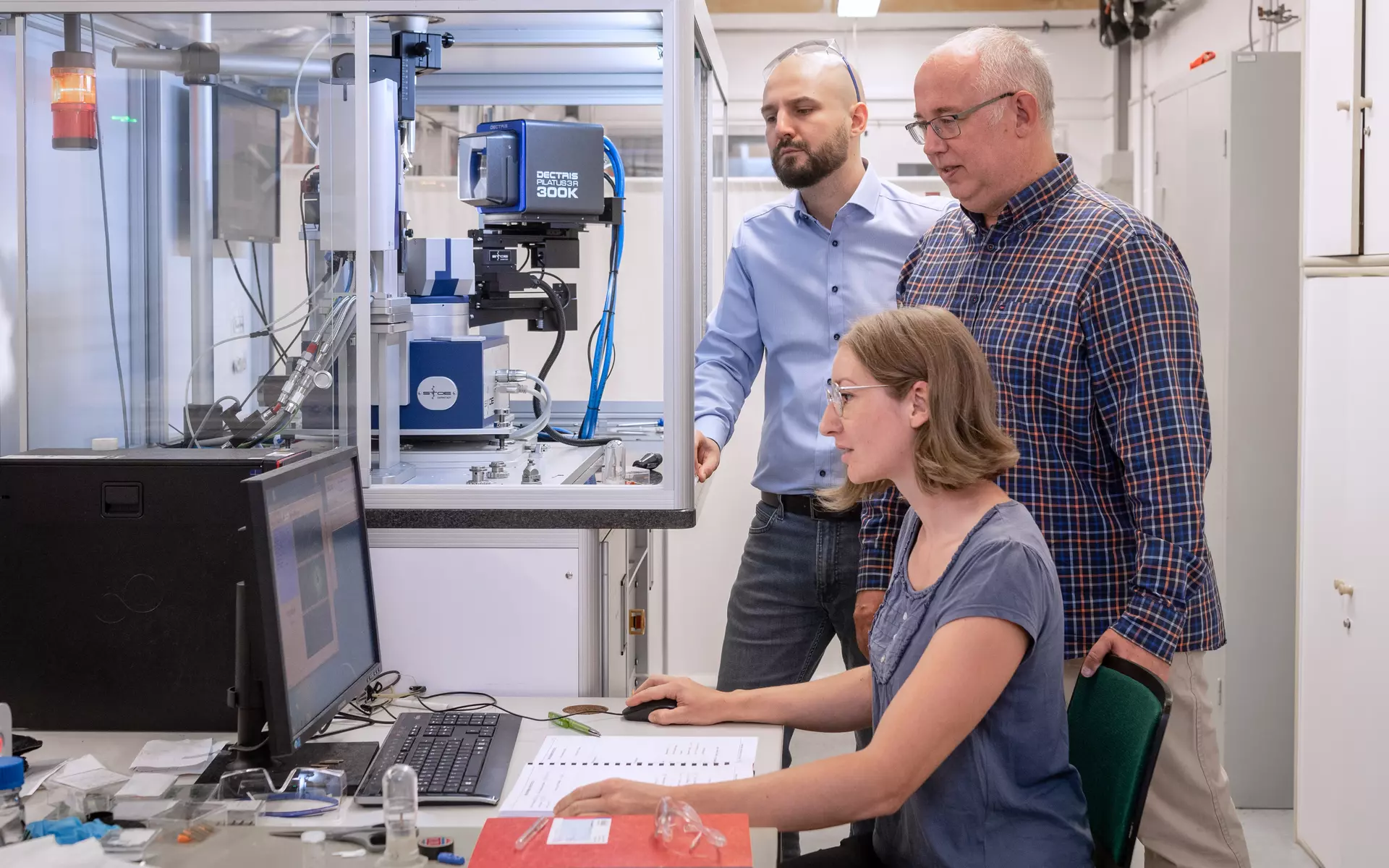

“We have now found a material which we can cause to be n-conducting or p-conducting simply by changing the temperature,” says Tom Nilges,professor of Synthesis and Characterisation of Innovative Materials at TUM. The researchers have been able to show that a temperature change of just a few degrees is enough to bring about this effect – and that a functioning diode can be created with a temperature gradient within the material.

“When the material is at room temperature, we have a completely normal p conductor. If we then apply a temperature gradient, we can simultaneously generate an n conductor in the heated areas,” explains Prof. Nilges. An important aspect for applications: the effect functions in room temperature ranges. “To generate a diode, a local temperature rise of just a few degrees is enough – in our case from 22 to 35°C.”

For Nilges, the elimination of the need for doping is not the only advantage: “Every diode that is produced is always there. With our material that is not the case: with the temperature gradient, the diode also disappears. If it is needed again, it is enough to create a temperature gradient. If we think about the range of applications for diodes, for example in solar cells or in every kind of electronic component, the potential of this invention becomes evident.”

Complex composition

The search for the perfect material involved 12 years of work, which has now culminated in the team’s discovery of the coinage metal chalcogenide halide Ag18Cu3Te11Cl3. It consists of the elements silver, copper, tellurium and chlorine. The researchers came across this class of compounds when exploring thermoelectric materials, which generate electricity from heat. One material they studied displayed the p-n switching effect. However, this was observed only in the temperature range around 100°C, which is unsuitable for practical applications.

After extensive analysis and experimentation, in Ag18Cu3Te11Cl3 the researchers discovered a material that displays the desired effect and is also suitable for applications at normal temperatures. “Other research groups have also discovered this switching effect in various materials, but so far nobody has managed to convert it into a specific application,” explains Nilges.

As the next step the researchers plan to show that their material can be used to create transistors through temperature changes.

New Material Will Make Locally Flexible Diodes Possible: Original Article

Record efficiency for perovskite-based light-emitting diodes