One of the first polymer case ammunition rounds for wide production in the Marine Corps will be for its heavy-duty machine gun, the venerable M2 .50 caliber Browning Machine Gun.

The Marine Corps recently announced its intent to sole source a company to build polymer casings for .50 caliber ammunition, the largest direct fire, bullet projectile in the ground combat arsenal and a mainstay of machine gunning for nearly a century.

MAC LLC, a company out of Bay Saint Louis, Mississippi, is the company that will likely receive the sole source contract unless another company can show they meet the requirements and can do a better job before the federal deadline in a couple of weeks to deliver an estimated quantity of 2.4 million cartridges for the Corps over three years.

It will be producing both ball and armor-piercing rounds.

The weight savings sought by the Corps aims to cut 20 pounds off of the current weight of a can of .50 caliber ammunition, or a cut of up to one-third of the existing load.

Marine Corps Systems Command posted the request in April 2018 and awarded this contract this April 1, according to a posting on fbo.gov, a federal government business website.

A belt of 100 lightweight .50-caliber cartridges with 101 links will have to see a 15 to 30 percent weight reduction under the Corps’ requirements listing.

And no performance can be sacrificed — the new cartridge must meet the same ballistics requirements and lethality of the M33 projectile in service now.

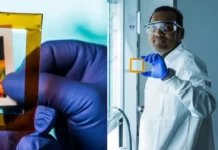

Polymer is the new steel in many of weapons accessories and ammo casings.

The Corps authorized the use of polymer magazines for the M27 Infantry Automatic Rifle in recent years.

Read more: Ammo for the Marine Corps .50 caliber is getting a whole lot lighter

thumbnail courtesy of marinecorpstimes.com

Related Links:

US Marines construct the world’s first 3D-printed barracks hut