Founded by MIT chemical engineers and winner of an XPRIZE Carbon Removal milestone award, Verdox is working to move the needle on climate change.

Department of Chemical Engineering

Cracking the Carbon Removal Challenge: By most measures, MIT chemical engineering spinoff Verdox has been enjoying an exceptional year. The carbon capture and removal startup, launched in 2019, announced $80 million in funding in February from a group of investors that included Bill Gates’ Breakthrough Energy Ventures. Then, in April — after recognition as one of the year’s top energy pioneers by Bloomberg New Energy Finance — the company and partner Carbfix won a $1 million XPRIZE Carbon Removal milestone award. This was the first round in the Musk Foundation’s four-year, $100 million-competition, the largest prize offered in history.

“While our core technology has been validated by the significant improvement of performance metrics, this external recognition further verifies our vision,” says Sahag Voskian SM ’15, PhD ’19, co-founder and chief technology officer at Verdox. “It shows that the path we’ve chosen is the right one.”

The search for viable carbon capture technologies has intensified in recent years, as scientific models show with increasing certainty that any hope of avoiding catastrophic climate change means limiting CO2 concentrations below 450 parts per million by 2100. Alternative energies will only get humankind so far, and a vast removal of CO2 will be an important tool in the race to remove the gas from the atmosphere.

Voskian began developing the company’s cost-effective and scalable technology for carbon capture in the lab of T. Alan Hatton, the Ralph Landau Professor of Chemical Engineering at MIT. “It feels exciting to see ideas move from the lab to potential commercial production,” says Hatton, a co-founder of the company and scientific advisor, adding that Verdox has speedily overcome the initial technical hiccups encountered by many early phase companies. “This recognition enhances the credibility of what we’re doing, and really validates our approach.”

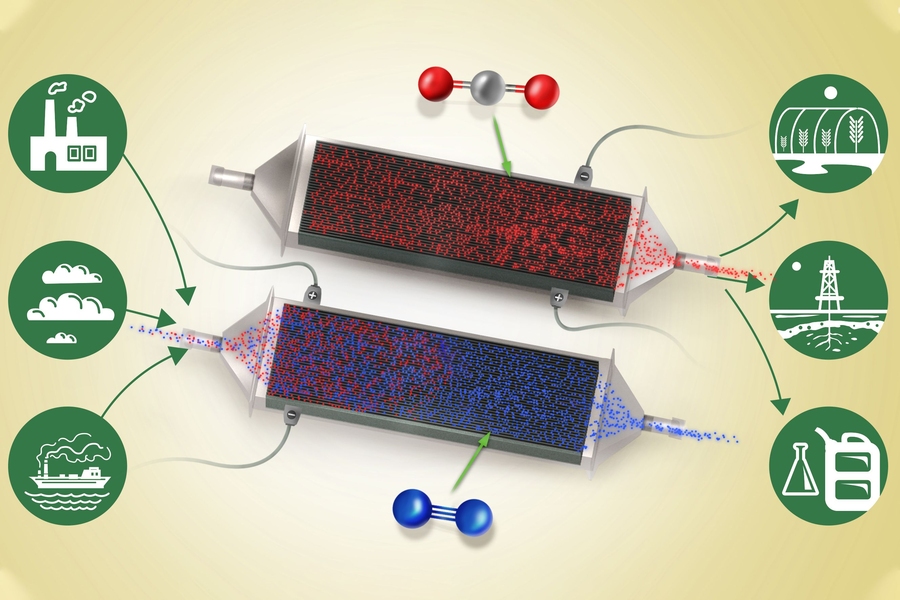

Cracking the Carbon Removal Challenge: At the heart of this approach is technology Voskian describes as “elegant and efficient.” Most attempts to grab carbon from an exhaust flow or from air itself require a great deal of energy. Voskian and Hatton came up with a design whose electrochemistry makes carbon capture appear nearly effortless. Their invention is a kind of battery: conductive electrodes coated with a compound called polyanthraquinone, which has a natural chemical attraction to carbon dioxide under certain conditions, and no affinity for CO2 when these conditions are relaxed. When activated by a low-level electrical current, the battery charges, reacting with passing molecules of CO2 and pulling them onto its surface. Once the battery becomes saturated, the CO2 can be released with a flip of voltage as a pure gas stream.

“We showed that our technology works in a wide range of CO2 concentrations, from the 20 percent or higher found in cement and steel industry exhaust streams, down to the very diffuse 0.04 percent in air itself,” says Hatton. Climate change science suggests that removing CO2 directly from air “is an important component of the whole mitigation strategy,” he adds.

“This was an academic breakthrough,” says Brian Baynes PhD ’04, CEO and co-founder of Verdox. Baynes, a chemical engineering alumnus and a former associate of Hatton’s, has many startups to his name, and a history as a venture capitalist and mentor to young entrepreneurs. When he first encountered Hatton and Voskian’s research in 2018, he was “impressed that their technology showed it could reduce energy consumption for certain kinds of carbon capture by 70 percent compared to other technologies,” he says. “I was encouraged and impressed by this low-energy footprint, and recommended that they start a company.”

Neither Hatton nor Voskian had commercialized a product before, so they asked Baynes to help them get going. “I normally decline these requests, because the costs are generally greater than the upside,” Baynes says. “But this innovation had the potential to move the needle on climate change, and I saw it as a rare opportunity.”

Cracking the Carbon Removal Challenge: The Verdox team has no illusions about the challenge ahead. “The scale of the problem is enormous,” says Voskian. “Our technology must be in a position to capture mega- and gigatons of CO2 from air and emission sources.” Indeed, the International Panel on Climate Change estimates the world must remove 10 gigatons of CO2 per year by 2050 in order to keep global temperature rise under 2 degrees Celsius.

To scale up successfully and at a pace that could meet the world’s climate challenge, Verdox must become “a business that works in a technoeconomic sense,” as Baynes puts it. This means, for instance, ensuring its carbon capture system offers clear and competitive cost benefits when deployed. Not a problem, says Voskian: “Our technology, because it uses electric energy, can be easily integrated into the grid, working with solar and wind on a plug-and-play basis.” The Verdox team believes their carbon footprint will beat that of competitors by orders of magnitude.

The company is pushing past a series of technical obstacles as it ramps up: enabling the carbon capture battery to run hundreds of thousands of cycles before its performance wanes, and enhancing the polyanthraquinone chemistry so that the device is even more selective for CO2.

After hurtling past critical milestones, Verdox is now working with its first announced commercial client: Norwegian aluminum company Hydro, which aims to eliminate CO2 from the exhaust of its smelters as it transitions to zero-carbon production.

Verdox is also developing systems that can efficiently pull CO2 out of ambient air. “We’re designing units that would look like rows and rows of big fans that bring the air into boxes containing our batteries,” he says. Such approaches might prove especially useful in locations such as airfields, where there are higher-than-normal concentrations of CO2 emissions present.

All this captured carbon needs to go somewhere. With XPRIZE partner Carbfix, which has a decade-old, proven method for mineralizing captured CO2 and depositing it in deep underground caverns, Verdox will have a final resting place for CO2 that cannot immediately be reused for industrial applications such as new fuels or construction materials.

With its clients and partners, the team appears well-positioned for the next round of the carbon removal XPRIZE competition, which will award up to $50 million to the group that best demonstrates a working solution at a scale of at least 1,000 tons removed per year, and can present a viable blueprint for scaling to gigatons of removal per year.

Can Verdox meaningfully reduce the planet’s growing CO2 burden? Voskian is sure of it. “Going at our current momentum, and seeing the world embrace carbon capture, this is the right path forward,” he says. “With our partners, deploying manufacturing facilities on a global scale, we will make a dent in the problem in our lifetime.”

Cracking the Carbon Removal Challenge: Original Article

Breakthrough Carbon Capture Conversion for Ethylene Production

Researchers are developing fast-charging solid-state batteries

Tokyo Creates Inexpensive Catalyst Efficient Carbon Dioxide Reduction